Product description:

Square and rectangular sectioned steel pipes are collectively referred to as square and rectangular sectioned steel pipes, and they belong to a type of welded steel pipes. They are also known as "steel cold-formed sections".

Due to their unique cross-sectional shape and excellent mechanical properties, square and rectangular sectioned steel pipes are widely used in modern industries, construction and manufacturing, and have become an indispensable basic steel material.

Cold-drawn square and rectangular tubes are high-precision steel products manufactured through a cold drawing process to achieve excellent dimensional accuracy, smooth surface finish, and enhanced mechanical properties. These tubes are commonly used in mechanical structures, automotive systems, construction frameworks, hydraulic machinery, and precision instruments. The cold-drawing technique refines the internal grain structure of the steel, improving its strength, toughness, and surface quality compared to hot-rolled or welded alternatives.

Parameters:

Product Name: | Square Tube |

Material: | S355, S235, 1020, etc. |

Surface Finish: | TSHS |

Measurement: | Actual weight measurement |

Standards: | ASTM, AISI, DIN, EN, GB, JIS |

Section Shape: | Square/Rectangle |

Model: | 10*10 - 800*800*30, can be customized according to customer requirements |

Weld Shape: | Seamless |

Processing Services: | Bending, Welding, Unfolding, Punching, Cutting |

Type: | Welding, Seamless |

Brand: | Hengxin Zhicheng |

Applicable Industries: | Construction, Machinery, Construction Equipment, etc. |

Sales Unit: | Ton/Unit |

Port: | Shanghai Port or designated port |

Packaging Details: | Steel strip bundling, wooden box |

Payment Terms: | Telegraphic Transfer |

Trade Terms: | EXW, FOB, CIF, DAP, DDP |

Delivery Time: | 20 - 35 days |

Service: | OEM and ODM |

Minimum Order Quantity: | 1 ton |

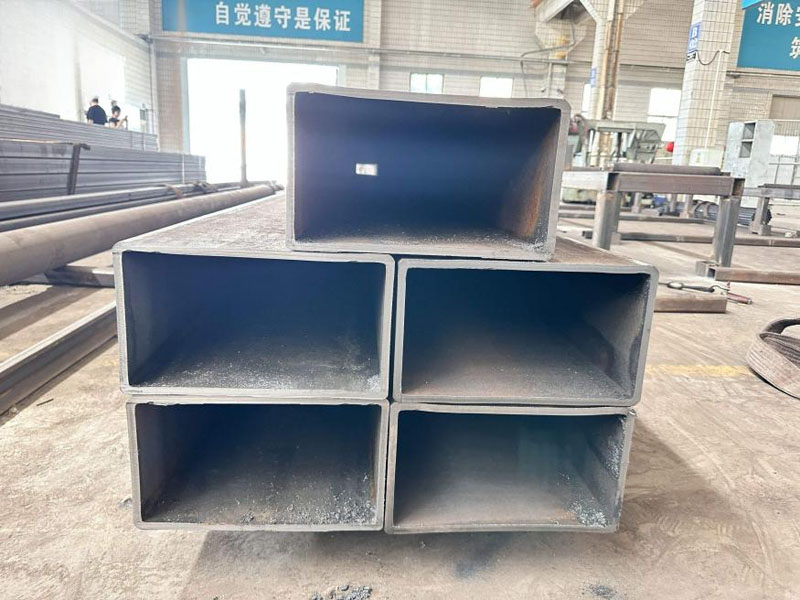

Pictures:

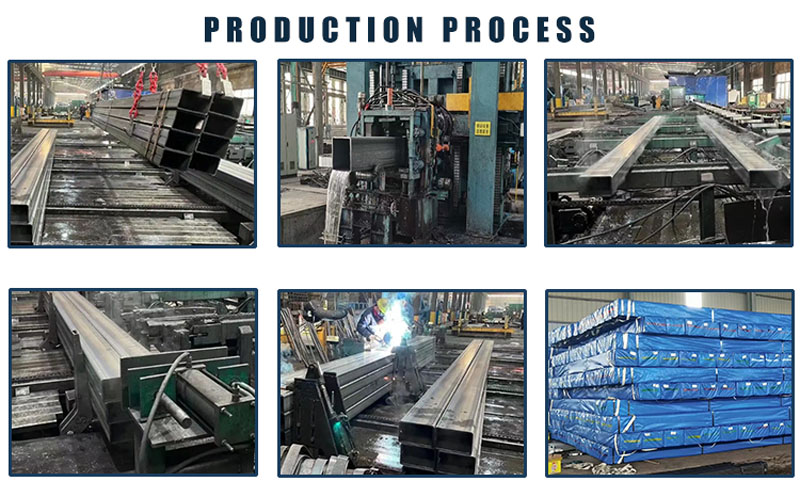

Manufacturing Process

The production of cold-drawn Square and rectangular tubes begins with a seamless or welded round tube as the base material. The process typically includes the following stages:

Preparation: The round tube is cleaned, pickled, and lubricated to reduce surface oxidation and friction during drawing.

Cold Drawing: Using high-precision dies and mandrels, the tube is drawn through a shaping process at room temperature to form a square or rectangular cross-section.

Heat Treatment: After drawing, the tube undergoes annealing or normalization to relieve internal stress and restore ductility.

Finishing: Tubes are straightened, cut to length, and surface-treated (oiled, polished, or coated) to ensure durability and corrosion resistance.

Inspection: Each tube is tested for dimensional tolerance, surface smoothness, and mechanical integrity using advanced non-destructive testing (NDT) methods such as ultrasonic or eddy current inspection.

This meticulous process results in a product that meets the highest standards of dimensional precision and mechanical reliability.

Material Grades

Cold-drawn square and rectangular tubes are produced from a variety of steel grades depending on the application requirements:

Carbon Steel: ST35, ST37.4, ST52, S235JR, S355J2, E235, E355

Alloy Steel: 20MnV6, 15CrMo, 42CrMo4, 4130, 4140

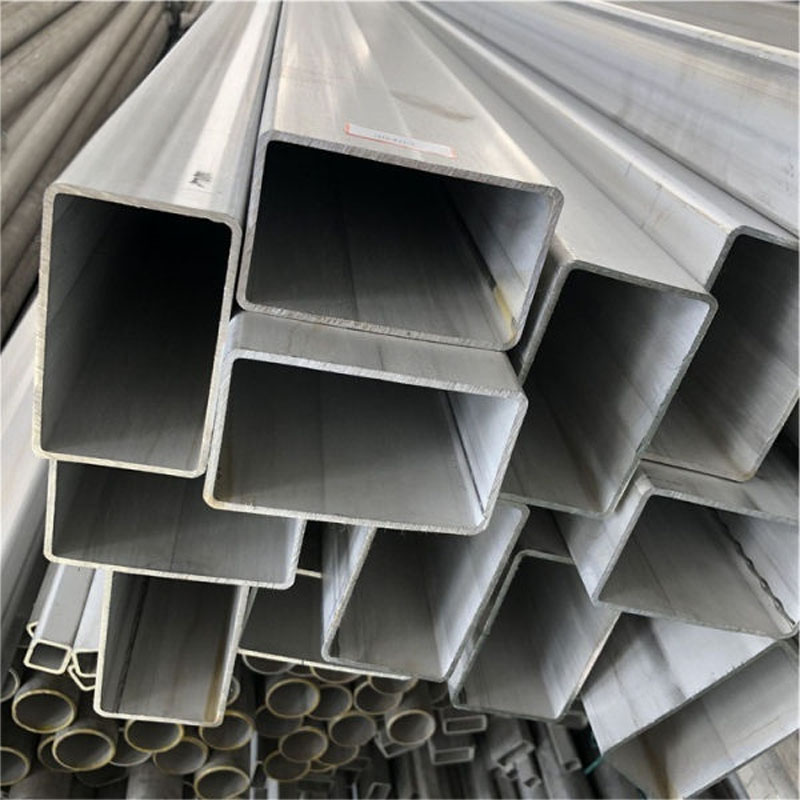

Stainless Steel: 304, 316L, 321, 310S

These grades offer combinations of tensile strength, corrosion resistance, and formability suitable for both industrial and decorative applications.

In stock:

Applications:

Cold-drawn square and rectangular tubes are widely used in various industries due to their strength, precision, and surface quality:

Mechanical Engineering: Shafts, machine frames, and precision components.

Automotive and Transportation: Axles, steering columns, and chassis frames.

Construction and Architecture: Structural frameworks, building supports, and decorative elements.

Hydraulic and Pneumatic Systems: Cylinders, actuators, and fluid lines requiring smooth surfaces.

Furniture and Equipment: Modern metal furniture, racks, and display systems.

Their combination of strength, precision, and aesthetic appeal makes them a preferred material for high-performance designs.

Quality Standards and Certifications

Cold-drawn square and rectangular tubes meet or exceed international standards, including:

EN 10305-5 / EN 10305-1 – Precision steel tubes

DIN 2391 / DIN 2395 – Cold-drawn seamless and welded tubes

ASTM A513 / A519 – Mechanical and structural tubing

GB/T 3639 / GB/T 3094 – Precision cold-drawn steel tubes

ISO 9001 / CE / SGS – Quality management and safety certifications

These standards ensure product consistency, strength, and compliance with global engineering requirements.

Company profile:

Since its establishment in 2014, Wuxi Hengxin Zhicheng Co., Ltd. has rapidly grown into a leading enterprise in the steel manufacturing industry. We focus on the research, production and sales of seamless steel pipes, special-shaped steel pipes and hydraulic cylinders, and are committed to providing customers with high-quality, customizable products that fully meet diverse application needs.

Our products are exported to global markets such as the Middle East, South America, Africa, and Southeast Asia, and are highly trusted by large purchasers and customers in the steel industry. We always prioritize quality, reliability and customer service, and attach great importance to establishing long-term and stable cooperative relationships with customers. We provide each customer with tailor-made solutions.

We continuously promote technological innovation and improve service capabilities and production efficiency. Through an efficient online platform, you can browse our best-selling products at any time and communicate with the sales and support teams in real time to conveniently obtain the information you need. We sincerely invite partners from all countries to visit, exchange and provide guidance, and jointly explore more possible cooperation opportunities!

Certification:

Packaging and Transportation:

【Package standard】

We use steel bands to tightly package the products into hexagonal bundles. The structure is stable and not prone to deformation. Each bundle is equipped with two high-strength nylon straps to ensure the safety and convenience of the lifting operation.

To meet various maritime transportation needs, we offer a range of customized packaging options, including full coverage with oilcloth, moisture-proof wooden boxes, and high-strength protective frame packaging, to ensure the maximum safety of goods during transportation.

【Guarantee for transportation】

We offer 20-foot and 40-foot standard container transportation services. Each container can carry up to 25 tons of goods and we can accept trial orders with a minimum of 5 tons. This allows for flexible adaptation to your purchasing scale. All packaging complies with maritime shipping standards to ensure that the goods are delivered to the destination efficiently and safely.

Why us?

We focus on the research, development, production and sales of seamless steel pipes, special-shaped steel pipes and hydraulic cylinders. We have a complete production chain and an advanced equipment system, including piercing machines, cold drawing machines, hot rolling machines, high-precision flaw detection and testing equipment. The company has passed multiple authoritative certifications such as ISO9001, API, SGS, CCS, DNV, ABS, CE, RoHS, etc., ensuring that each product complies with international standards. We are committed to providing customers with high-quality, customizable solutions to meet diverse application needs.

Relying on our own built processing base and modern workshops, combined with multiple branches and storage centers across the country, we have achieved sufficient inventory and efficient logistics coordination, significantly shortening the delivery cycle and ensuring the rapid delivery of orders.

We have established a complete service and support system. After the order is signed, the professional after-sales team can provide timely and safe on-site guidance and technical support to ensure that customers are at ease throughout the process from procurement to use.

FAQ:

1. Do you support customized design and production?

Sure. We have a professional engineering team that can conduct customized design and production with special sizes, control systems or OEM according to your requirements.

2. How fast can you deliver?

In stock sizes, it takes 3-5 days. For customized sizes, it takes 30-35 days.

3. What payment methods do you support?

We support TT payment. Generally, 30% to 50% of the payment is made in advance, and the remaining amount is paid before shipment.

4. Can you provide material certification (MTC)?

Yes, we will provide MTC to you after production is completed to ensure that the material quality meets the standards.

5. What is the minimum order quantity?

Generally, we accept trial orders. The minimum order quantity is 1-3 tons, which can be determined according to different products.

版权所有©2025无锡恒鑫志成国际贸易有限公司 保留所有权利申请

本网站使用 cookie 来确保您在我们的网站上获得最佳体验。